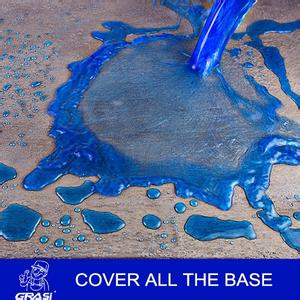

Nano Clear Coating is a one-component solvent borne clear coating that cures rapidly in the presence of atmospheric moisture. It forms an extremely cross-linked film with far superior scratch, abrasion, chemical and UV resistance over any leading two-component automotive OEM or aftermarket clear coating. Suitable for use over oxidized automotive, marine or aircraft clear coatings and topcoatings.

Conventional paint systems including epoxies provide good corrosion resistance and initial surface hardness, but unfortunately fall short in long-term UV resistance and weathering. Two-component polyurethanes provide good UV resistance and weathering, but typically cost much more than epoxy or polyester topcoats. Unfortunately conventional paint systems like topcoats and epoxies begin the oxidization process or ^chalking ̄ from weathering within 6 months from application. This surface chalking phenomenon is actually degraded paint that resides on the surface from UV exposure and weathering.

Nano Clear Coating Coatings penetrate deep into the smallest pores within newly painted or highly oxidized paint surfaces to form a highly cross-link dense / hard coat surface. Nano Clear Coating Coatings provide dramatically longer surface protection over conventional automotive, marine, aerospace and industrial paints including epoxies and polyurethanes.

How can we make this claim?

Nano Clear Coating Coatings provide dramatically higher crosslink density over conventional one-component and two-component coating systems. Nano Clear Coating Coatings prevent UV degradation of the substrate by absorbing harmful UV rays.Crosslink density is defined as the concentration of chemical bonds within a polymer. Higher concentrations of chemical bonds within a polymer improve physical properties. Conversely, lower concentrations of chemical bonds within a polymer decrease physical properties. Increasing crosslink density increases material hardness, chemical resistance and long-term UV resistance.

Dry film property*

Pencil Hardness Pendulum Hardness (Persoz)

Abrasion Resistance (CS-17, 1kg, 1000 cycles)

Impact Strength (kg-cm)

Water immersion test (240 hours @ 50<C) CASS @ 50<C %

Gloss retention (> 1500 hours QUV 313) % Gloss retention (> 2000 hrs Xenon WOM)

Nano-Clear 4H > 250 8.4 mg > 140 Pass Pass (240 hours) > 100 > 99

Test Method ASTM D3363 ASTM D4366 ASTM D4060 ASTM D2794 ISO 2812-2 JIS H8502-7 ASTM D4587 ASTM G155

*Fully cured clear coat on bare aluminum panels @ 72<F at RT for at least 24 hours prior to testing.

MEK resistance - > 1500 ASTM D4752

Where good ideas come to the surface

Contact: sales@coating-paint.com